|

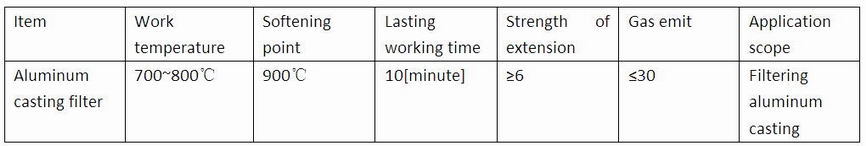

Aluminum casting filter:for filtering aluminum casting liquid

Aluminum casting filter is made by a woven grid from a specific high twist and strength E-glass fiber after special treatment. It is corrosion-resistant of aluminum liquid and chlorine fluoride and also high-temperature resistant. The net is widely applied in filtering aluminum and aluminum alloy solution in the temperature of 700 . If the flow is less than 10 kg per minute, it can be used continuously for 4 hours. If less than 120 kg per minute, it could be 1.5 hours. As perfect filtering material in the aluminum metal smelting process, the net is also able to clean out the oxides and other impurities suspending in the volume. This is used in ally type of aluminum alloy casting, as well as during the casting of sand, permanent molds, shell mold,the die and fired mold. The functions of eliminating impurities, turbulence and bubbles make further improvement on the quality and lower the cost. At the same time, the net do not contaminate aluminum liquid and affect chemical properties of metals, making it possible for the net to be remelt directly, so that the cost is saved. . If the flow is less than 10 kg per minute, it can be used continuously for 4 hours. If less than 120 kg per minute, it could be 1.5 hours. As perfect filtering material in the aluminum metal smelting process, the net is also able to clean out the oxides and other impurities suspending in the volume. This is used in ally type of aluminum alloy casting, as well as during the casting of sand, permanent molds, shell mold,the die and fired mold. The functions of eliminating impurities, turbulence and bubbles make further improvement on the quality and lower the cost. At the same time, the net do not contaminate aluminum liquid and affect chemical properties of metals, making it possible for the net to be remelt directly, so that the cost is saved.

Installing location

The casting filter could be cut into squares of any sizes by scissors and put under the runner cup or on the lap surface of runners or between the runners and gates for box compaction.Moreover, the filtering effect would be better, if using filter nets and scum risers together.

Products Features

1. Effectively remove detrimental impurity like the bubbles, the oxide inclusion and any other inclusion in aluminum solution,dramatically rising the yield and quality of the casting. By doing this, the disadvantage created by other metal composition coming into the solution can be avoided and the composition of aluminum alloy can be unaffected and the quality can be further assured.

2.Improve mechanical performance of the aluminum casting by adding and uniforming the surface hardness and heightening the bending strength.

3.Enhance machine's working ability by increasing the efficiency.

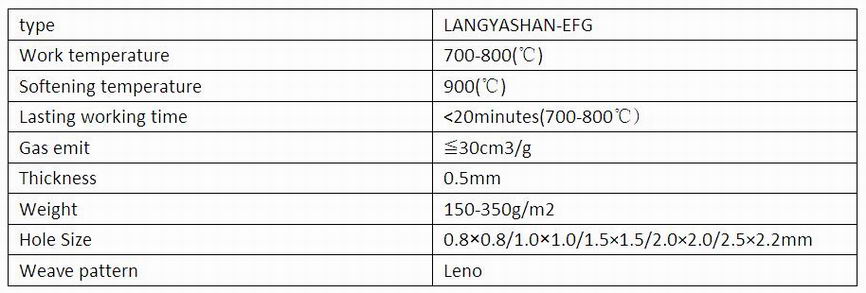

Technical specifications

|